What is PTFE sintering furnace?

PTFE sintering furnace is a special furnace applied to the drying of PTFE in the aviation, automotive, household appliances, scientific research and other fields, to test and determine the parameters and performance of electricians, electronics, products and materials after temperature changes.

Features and advantages

|

|

1. High temperature resistance, and excellent insulation performance.

2. Steam preheating and electric heating compensation are often used, resulting in high thermal efficiency and low operation cost.

3. The internal monitoring temperature is consistent with PTFE temperature, and heating, draining, drying and cooling functions can meet the requirements of PTFE drying process.

4. PTFE sintering furnace runs smoothly with the minimized noise.

5. Easy installation and maintenance, and intelligent human-machine interface operation.

Components

The PTFE sintering furnace is mainly composed of furnace body, hearth, steam heat exchanger, electric heater, support, circulating fan, moisture discharging fan, refractory material and electric heating device, etc.

1. The furnace body has the frame structure, and its full-welding inner cavity, making it easier to clean.

2. Composite insulation minimizes the heat transferred between inner skeleton and outer skeleton. Unexposed insulation materials ensure that the average temperature rise of the outer wall of the furnace body remains within 20 ℃ higher than the ambient temperature, thus effectively preventing heat loss.

3. The hearth is firm and durable, and will not be deformed. Pressure bar locks are used in the hearth and the furnace body. Silicone rubber is used as the sealing material, to ensure that the hearth is sealed tightly.

4. Preheating of steam heater and compensation of electric heater inside the furnace realizes the temperature control accuracy of ±0.5 ℃. Multi-point dual-setting temperature measurement ensures true and reliable monitoring temperature and provides over-temperature alarm function.

5. Axial circulating fan with large air volume and low noise, together with movable perforated plate, ensures uniform temperature in the PTFE sintering furnace and avoids dust flying.

6. The bearing seat of the circulating fan is well sealed and equipped with oil slinger, to prevent lubricants into the furnace.

7. Controlled by frequency conversion, the moisture discharging fan discharges the moisture according to the process requirements.

|

|

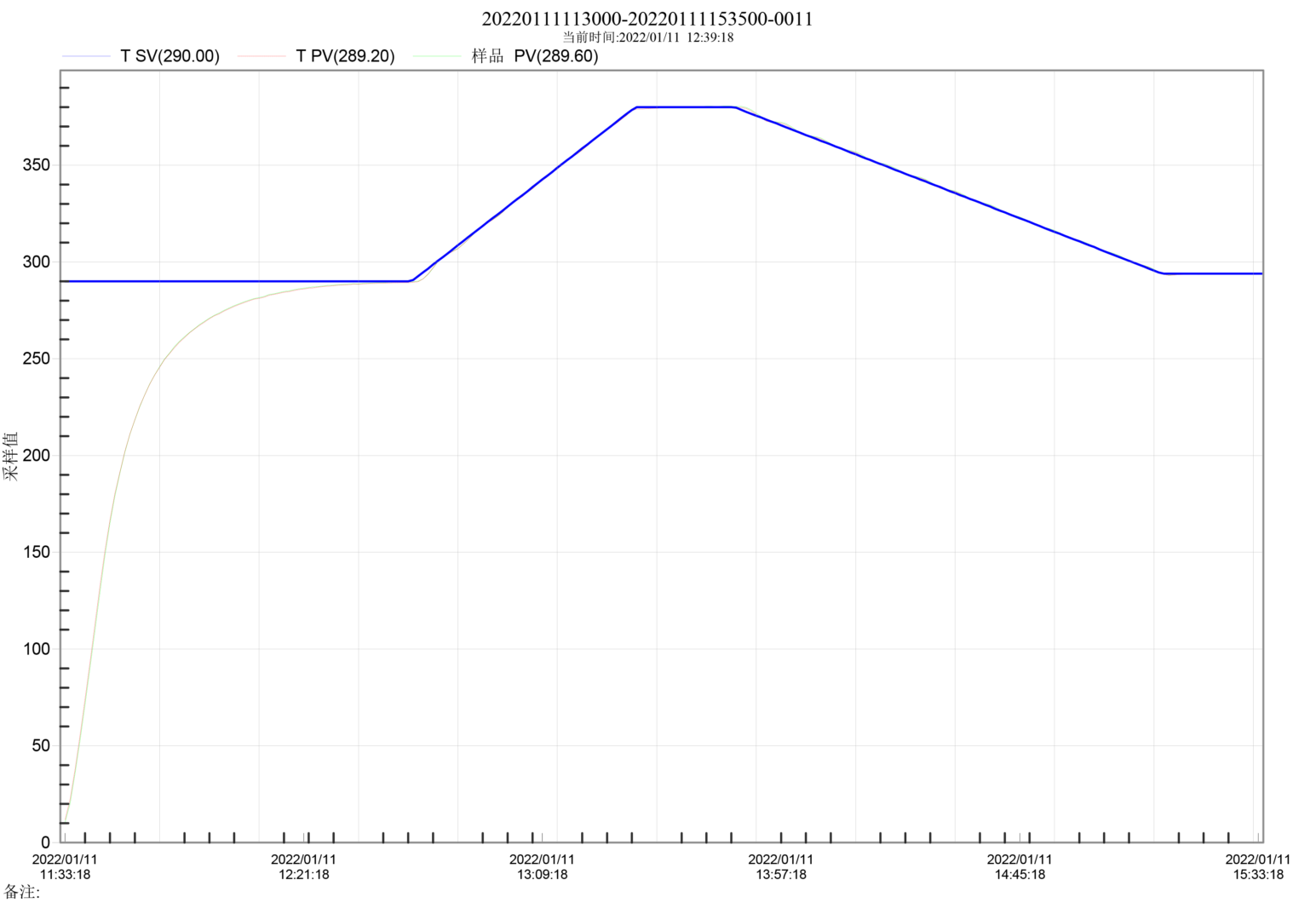

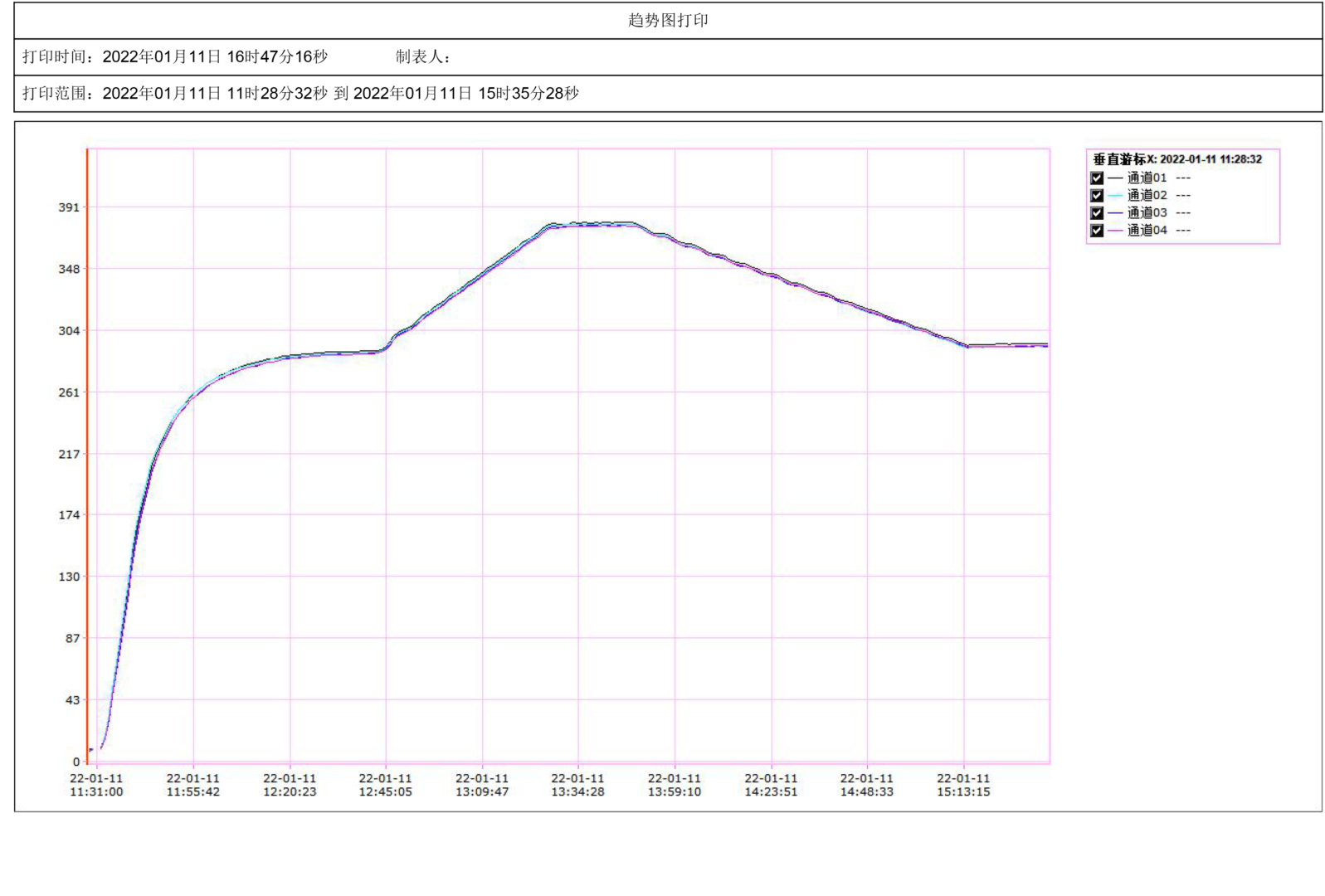

SuKo Polymer Machine Tech Co., Ltd. As an experienced and patented manufacturer, we manufacture PTFE sintering furnaces. It can ensure that the temperature in the corner of the furnace is almost the same as that in the center, and the temperature can be accurately changed according to the setting of the control panel. Temperature sensor tests at the corner and center are shown as follows:

|

|

Corner temperature detector temperaturerecording curve |

Central temperature detector temperaturerecording curve |

No comments:

Post a Comment