Tuesday, May 24, 2022

Monday, May 23, 2022

EVERYTHING YOU NEED TO KNOW ABOUT PTFE RODS

What is a PTFE rod?

PTFE rods, also known as Teflon rods, are unfilled PTFE resin (can contain recycled PTFE resin) molded, paste extruded or plunger extruded for processing various gaskets, seals and lubricating materials that work in corrosive media and electrical insulation parts used at various frequencies. Plunger extrusion process to form the rod.

|

|

Main properties of PTFE rod

Operating temperature: from -200℃ to 260℃; easy processability; aging resistance: it can be exposed to ozone and sunlight for a long time without aging; corrosion resistance: it can withstand strong acids, strong oxidizing agents, strong reducing agents and various organic solvents except molten alkali metals and fluorinated media; outstanding electrical insulation properties.

Other characteristics

Density: 2.16-2.20g/cm3; volume resistance>1×1018; surface resistance>2×1013; arc resistance>165s; water absorption<0.1%; low friction coefficient; non-adhesive surface: solid materials cannot adhere to its surface; non-combustibility: it will not burn in the air; non-toxic: it’s non-toxic, odorless and physiologically inert, and causes no harm to people and the environment.

Applications of PTFE rod

There are two kinds of PTFE rods: pressed rods and molded rods. Due to excellent chemical resistance and dielectric properties, and minimized friction coefficient, PTFE rods are mainly applied to long products and mechanical parts with non-standard specifications such as seals/gaskets, rings, wear-resistant plates/seat electricity, insulating parts, mechanical parts, and linings in the fields of oil and gas, petrochemical, chemical, instrument and equipment.

Chemical industry: It can be used as anti-corrosion material, produce various anti-corrosion parts, such as pipes, valves, pumps and pipe fittings, and act as the linings and coatings of reactors, distillation towers and anti-corrosion equipment.

Mechanical industry: It can be used as self-lubricating bearings, piston rings, oil seals and sealing rings, etc. Its self-lubrication can reduce wear and heat generation of machine parts and reduce power consumption.

Electronic appliances: It is mainly used in the manufacture of various wires and cables, battery electrodes, battery separators, and printed circuit boards, etc.

Medical materials: Its heat-resistant, water-resistant and non-toxic properties enables itself to be used as sealing and filling materials for medical devices (sterilization filters, beakers, artificial heart and lung devices) and artificial organs (artificial blood vessels, heart and esophagus).

SuKo PTFE Teflon Rod Extruder

1. Complete set of ptfe equipment manufacturer - Push bar machine line: bar extruder, mold design, heating ring, automatic feeding one-stop service.

2. PLC intelligent control: continuous extrusion, sintering, self-adjusting concentricity, automatic feeding, feeding equipment can be used for 6-8 hours, no manual.

3. Extrusion rod quality: smooth surface, high tensile strength, high density.

4. Professional technical guidance: installation and debugging, operation and operation, process setting, maintenance, after-sales service, raw material channel.

Monday, May 16, 2022

THREE COMMON PROBLEMS WITH PTFE TUBES

PTFE tube or Teflon tube, a semi-transparent, chemically inert and non-toxic material, has been mostly used in applications requiring resistance to high temperatures, including medical and health care, chemical, aviation, national defense, cutting-edge science and technology, and mechanical engineering, etc. One of its unique features is temperature resistance and its working temperature is from -190℃ to +260℃, so it can be used in elevated temperature applications which require high temperatures of over 200℃. PTFE tubes have very good chemical resistance to common solvents, acids, alkali and bases, and excellent dielectric insulation properties.

|

|

Do you meet any problems when using a PTFE tube? Here SuKo Polymer Machine Tech Co., Ltd., a well-known China PTFE tube manufacturer and exporter, explains three typical problems to help you make better use of PTFE tubes.

1. How to connect PTFE tubes?

The continuous advancement of anti-corrosion technologies and innovation of anti-corrosion materials promote PTFE to be an attractive anti-corrosion material due to its excellent chemical stability, and high temperature and chemical corrosion resistance. But PTFE material has high lubricity and non-adhesive property, making it difficult to connect PTFE tubes. To solve this problem, hot air welding method and manual flanging method can be adopted to connect PTFE tubes.

2. Precautions of PTFE tube installation

The lined plastic is soft when drilling, but it is more troublesome to force a rigid drill bit, which will easily destroy the internal steel lined plastic pipe and cause edges to be hard to be flush, so it is recommended to use a cutter to open the hole. Lined plastic residues will fall into the original PTFE tubes during the hole opening process, so you should pay more attention during the operation, otherwise it will lead to blocked end water points. No electric welding tool should be used for punching holes or installing branch pipes, otherwise lined plastic of steel PTFE tubes will be destroyed.

3. How to treat the surface of PTFE tubes?

The surface of a PTFE tube should not come into contact with aggressive materials such as oil, solvents, and corrosive materials, etc. The surface should be cleaned with water and detergent and rinsed well after staining. The use of solvents and corrosive cleaning materials is prohibited.

You may encounter other problems when use a PTFE tube except these three problems, and don’t worry. You can find SuKo and will get necessary guidance and help.

Tuesday, May 10, 2022

Sunday, May 8, 2022

What is PTFE sintering furnace?

PTFE sintering furnace is a special furnace applied to the drying of PTFE in the aviation, automotive, household appliances, scientific research and other fields, to test and determine the parameters and performance of electricians, electronics, products and materials after temperature changes.

Features and advantages

|

|

1. High temperature resistance, and excellent insulation performance.

2. Steam preheating and electric heating compensation are often used, resulting in high thermal efficiency and low operation cost.

3. The internal monitoring temperature is consistent with PTFE temperature, and heating, draining, drying and cooling functions can meet the requirements of PTFE drying process.

4. PTFE sintering furnace runs smoothly with the minimized noise.

5. Easy installation and maintenance, and intelligent human-machine interface operation.

Components

The PTFE sintering furnace is mainly composed of furnace body, hearth, steam heat exchanger, electric heater, support, circulating fan, moisture discharging fan, refractory material and electric heating device, etc.

1. The furnace body has the frame structure, and its full-welding inner cavity, making it easier to clean.

2. Composite insulation minimizes the heat transferred between inner skeleton and outer skeleton. Unexposed insulation materials ensure that the average temperature rise of the outer wall of the furnace body remains within 20 ℃ higher than the ambient temperature, thus effectively preventing heat loss.

3. The hearth is firm and durable, and will not be deformed. Pressure bar locks are used in the hearth and the furnace body. Silicone rubber is used as the sealing material, to ensure that the hearth is sealed tightly.

4. Preheating of steam heater and compensation of electric heater inside the furnace realizes the temperature control accuracy of ±0.5 ℃. Multi-point dual-setting temperature measurement ensures true and reliable monitoring temperature and provides over-temperature alarm function.

5. Axial circulating fan with large air volume and low noise, together with movable perforated plate, ensures uniform temperature in the PTFE sintering furnace and avoids dust flying.

6. The bearing seat of the circulating fan is well sealed and equipped with oil slinger, to prevent lubricants into the furnace.

7. Controlled by frequency conversion, the moisture discharging fan discharges the moisture according to the process requirements.

|

|

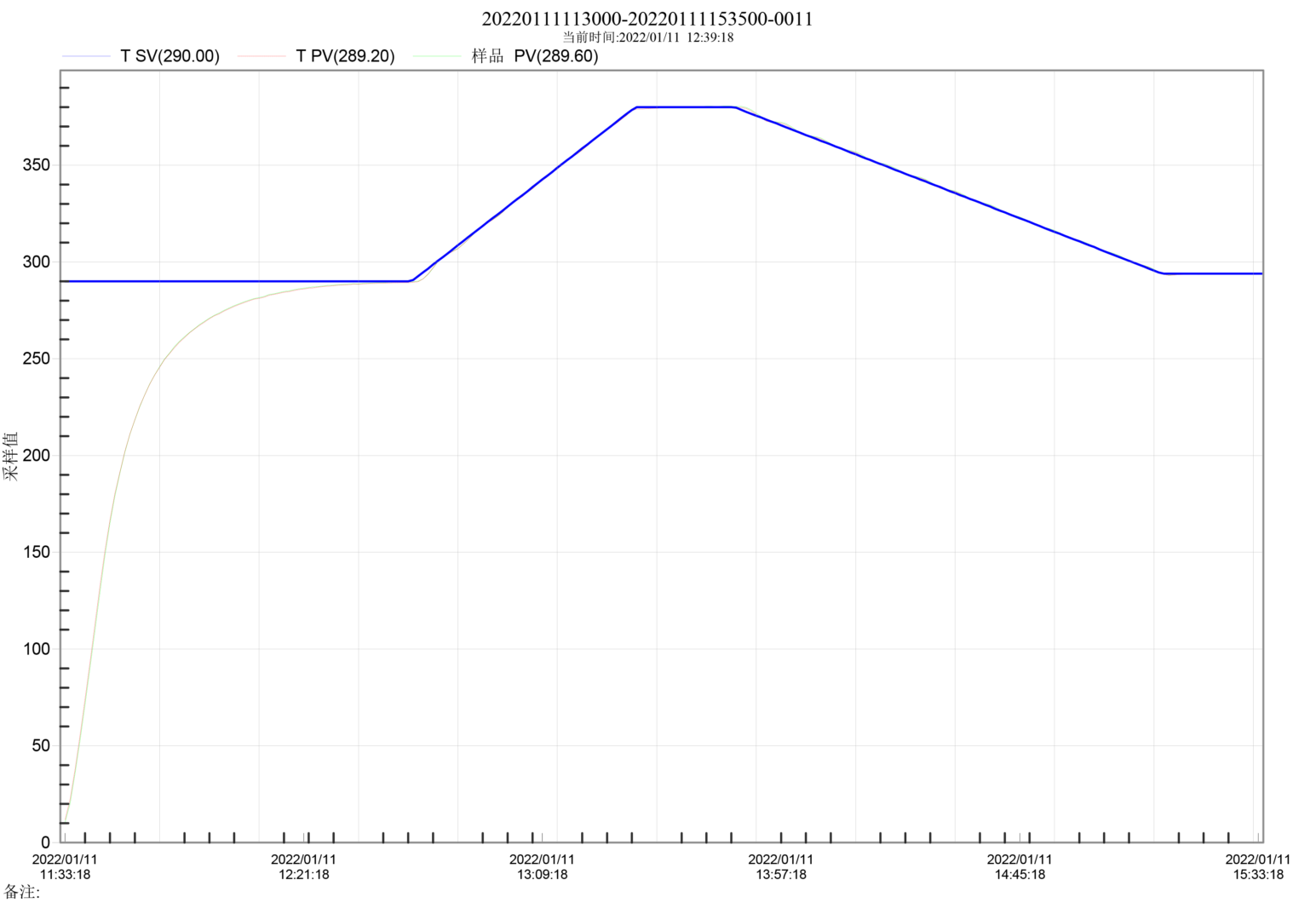

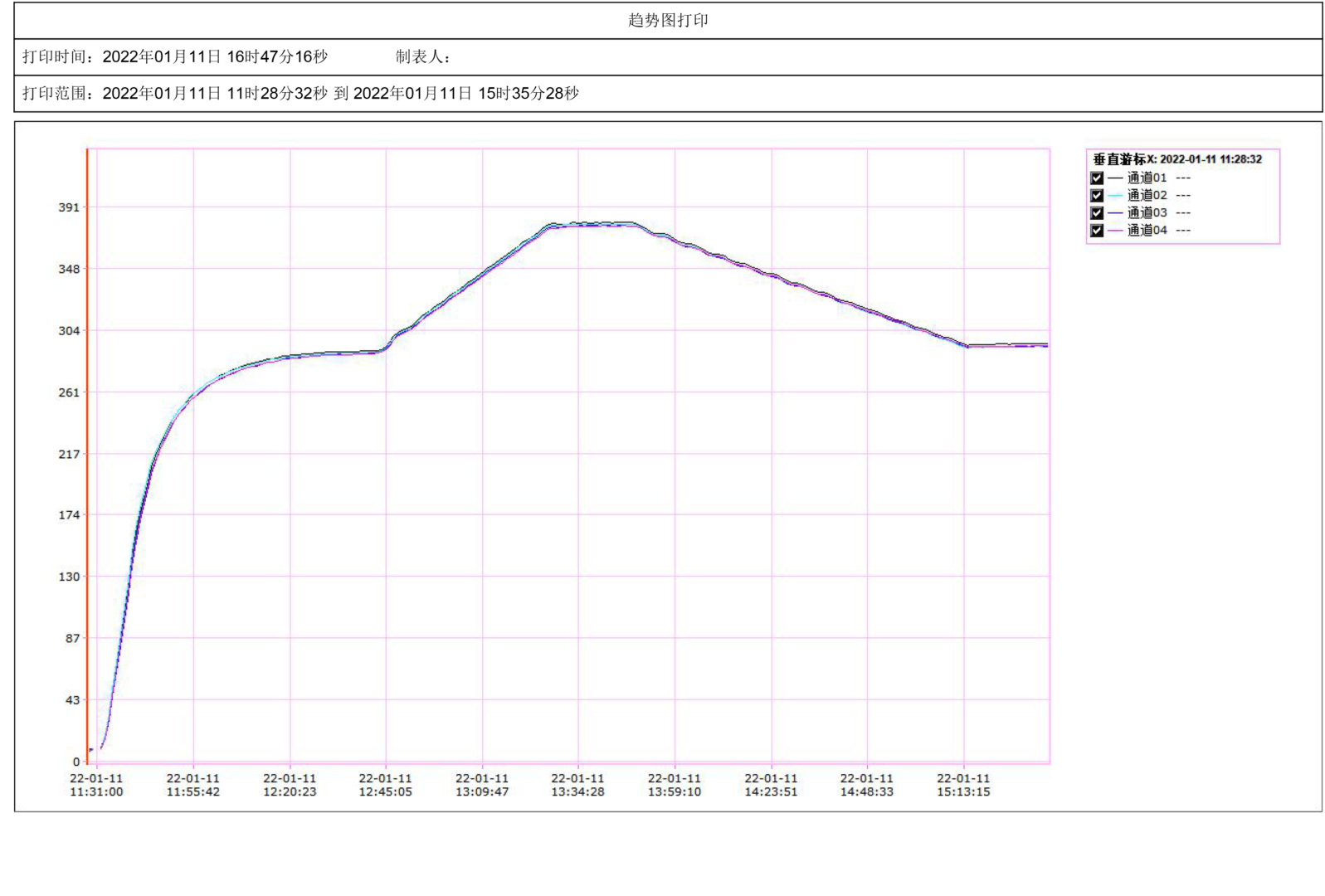

SuKo Polymer Machine Tech Co., Ltd. As an experienced and patented manufacturer, we manufacture PTFE sintering furnaces. It can ensure that the temperature in the corner of the furnace is almost the same as that in the center, and the temperature can be accurately changed according to the setting of the control panel. Temperature sensor tests at the corner and center are shown as follows:

|

|

Corner temperature detector temperaturerecording curve |

Central temperature detector temperaturerecording curve |

Wednesday, May 4, 2022

TEFLON GASKETS SEE SIGNIFICANT GROWTH POTENTIAL DUE TO GROWING DEMAND FROM EMERGING MARKETS

Teflon gaskets are acid and alkali resistant, high temperature resistant, and resistant to various organic solvents, and have been widely used in the chemical and pharmaceutical industries and are the originator of the gasket industry. Teflon gaskets can be divided into modified Teflon gaskets, expanded Teflon gaskets and pure Teflon gaskets according to material properties. At present, pure Teflon gasket is the most widely used gasket, and accounted for 34.56% of the market share in 2019.

1. Chemical and petrochemical are the largest downstream application markets

In terms of downstream applications, Teflon gaskets are mainly used in the sectors of energy, chemical & petrochemical, pharmaceutical, and oil & gas, etc. Among them, chemical & petrochemical occupies the largest share with 26.24% in 2019, followed by energy sector with 16.32% market share, and oil & gas sector ranks third with 15.17% share. The pharmaceutical and agriculture sectors occupy a relatively low market share of 12.40% and 9.22%, respectively.

2. Europe becomes the largest revenue market and Teflon gasket is expected to increase its market share in China in the forecast period

Studies have shown that Europe and the U.S. are the first and second largest revenue markets in the global Teflon envelope gasket industry, with the market sizes reaching USD 504 million and USD 456 million respectively in 2019, accounting for 36.57% and 33.13% of the global market respectively, and accounting for nearly 70% of the global market in total; while China ranks third with a market size of USD 169 million in the global market, accounting for 12.28% of the global market. In addition, important economies like Japan and India also have a share in the industry and play an important role in driving the growth of the global market.

Based on the available data, and taking into account the market environment and development patterns in each region, SuKo Polymer Machine has forecasted the future market landscape, and expects that the market share in each region will change to varying degrees in the future. By 2027, the market share in countries such as the United States, China and India will increase to a certain extent. The United States will replace Europe as the top market with a share of 35.05%, China’s share will rise to 13.30%, and India’s market share will rise from 1.90% in 2019 to 1.94% in 2027; the share of Teflon gaskets in Southeast Asia will also rise from 1.18% to 1.24%. On the contrary, the market share in Europe, Japan and other regions will decline at different levels.

3. Industry market size continues to rise and is expected to reach USD 1.861 billion in 2027

According to data, the global Teflon gasket industry had a market size of USD 1.100 billion in 2015, and then increased year by year to USD 1.377 billion in 2019, with a CAGR of 5.78% from 2015-2029. On the basis of this, a series of functional calculations were performed to scientifically derive the data for the next 8 years. Finally, it can be predicted that the market size of the global Teflon gasket industry will continue to rise during the forecast period and will rise to USD 1.861 billion by 2027.

The TOP three companies in the industry are Teadit, Freudenberg Sealing Technologies, and ERIKS NV. Teadit is a U.S. company that offers carbon fiber and graphite, synthetic fiber and aramid yarns, bushing materials, oxygen equipment, and compressed fiberboard high-temperature gasket materials. In 2019, Teadit Teflon envelope gasket market was valued at USD 0.067 billion. Freudenberg Sealing Technologies (FST), a German company, is the leader in global sealing technology market, offering accumulators, dust boots, engineered molding solutions, hydrodynamic seals, gaskets, piston seals, and thermoplastic seals with a global presence. ERIKS NV is a Dutch company offering a wide range of technical products, including seals and polymers, Teflon gaskets, valves and instruments, industrial and hydraulic hoses, industrial plastics, power transmission and bearings, conveyor systems and tools, maintenance and safety products, etc.

In 2019, the market shares of Teadit, Freudenberg Sealing Technologies and ERIKS NV in the global Teflon gasket industry were 4.72%, 2.64%, and 1.63% respectively, with a total market share of only 8.99% or less than 10%, and only 13.04% for CR6. It can be seen that the industry has low concentration ratio, and many small and medium-sized enterprises are involved in the industry, resulting in quite fierce competition.

Technological innovation is an important driver of market growth. To remain competitive in a highly competitive market, suppliers should develop new ideas and technologies and keep pace with advanced technologies. Teflon gasket manufacturers also need to constantly update and improve their products and change products according to the changing market needs. Improvements in Teflon material and reduction in gasket area will be new growth areas for the industry.

Teflon’s many performance advantages lead to its increasing use as a gasket material. These performance advantages include excellent water resistance, thermal insulation, resistance to most chemicals, and the ability to operate at extreme temperatures of -400 degrees Fahrenheit or 500 degrees Fahrenheit. In addition, PTFE meets strict FDA regulations, making it extremely useful in the food and pharmaceutical industries. In the future, Teflon envelope gaskets will gain more opportunities in the pharmaceutical industry with the rapid growth of the medical and pharmaceutical industries.

5. Sensitivity to cold flow is a new obstacle to market development

Low grade Teflon gaskets are made of pure PTFE resin material, which has the disadvantage of being very sensitive to cold flow and therefore its industrial applications are limited to low pressure and low temperature situations. Two methods are available to overcome the disadvantage of high sensitivity to cold flow or creep of pure PTFE material. The first method is to add filler to the resin and the other is to expand PTFE. PTFE with filler may become more commonly used in industrial sealing applications, and PTFE itself is very resistant to corrosion. Therefore, the aging resistance of the filler must be considered when adding the filler to PTFE, which has become a new restriction on gaskets.