Saturday, December 17, 2022

Ingredients for PTFE products - PTFE Teflon Pure Virgin Powder

Tuesday, September 13, 2022

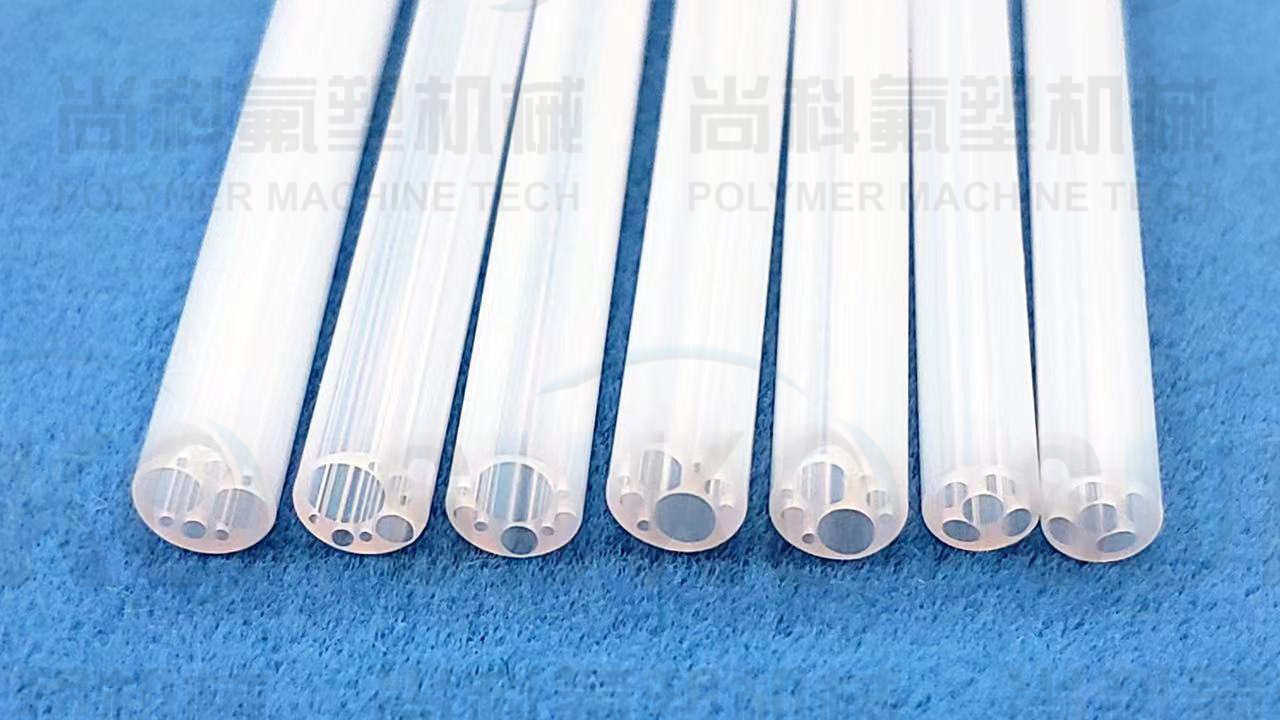

Seal Testing Of Multi Lumen Medical Tubing

The quality of medical devices bears upon the health and safety of patients, so the quality testing of medical devices is extremely strict. Medical products will be subject to various quality tests before leaving the factory, most of which have to receive seal testing, e.g., multi lumen tubing used in a multitude of minimally invasive clinical procedures. In order to help you better understand how manufacturers conduct seal testing of medical multi-lumen tubes, SuKo will share with you a case of medical multi-lumen tube seal testing.

Multi-lumen tubing has a single tube with multiple internal pathways/lumens isolated from one another. The central venous catheter in a multi-lumen tubing has a cut-out tip with small holes exiting from each lumen. A tooling fixture needs to be made to snap and seal the tubing before the seal testing.

To conduct seal testing of multi-lumen tubing, an air tightness tester with 4 test ports should be used with a tooling fixture using pressure-decay method. Before testing, the test pressure, inflation time, pressure stabilization time, test time and upper limit of leakage rate should be set on the air tightness tester, and the multi-lumen tubing should be placed in the fixture, with the proximal end of the lumen connected to the appropriate port and the distal end sealed.

When the tester is started, each lumen is tested individually for leaks, while all other untested lumens are vented. In this way, the leak test detects any cross-lumen leaks as well as leaks outside the multi lumen medical tubing. Once the leak test is completed, the tester will display the final test results with a green light for PASS and a red light for FAIL.

If you have any medical multi-lumen tubing to receive seal testing, please find third-party inspection organization with CMA and CNAS certification.

Monday, September 12, 2022

PTFE Products - Teflon PTFE Filter Bag

Monday, September 5, 2022

PTFE Products - PTFE Teflon Wire

Thursday, September 1, 2022

PTFE Products - Teflon Glass Fabric

Tuesday, August 30, 2022

PTFE Products - Teflon PTFE Hose Pipe Tube

Monday, August 29, 2022

PTFE Plays A Vital Role In The Turn Of Cable-stayed Bridge

China’s first sea-crossing high-speed railway between Fuzhou and Xiamen is coming, on which the cable-stayed bridge has been built successfully with the help of PTFE polytetrafluoroethylene, the king of plastics. Let’s talk about an application of PTFE that is little known to you.

Taicheng Xite Bridge is one of the bridges between Fujian and Xiamen High-speed Railway. The bridge is designed as an unbalanced rotating cable-stayed bridge with a total weight of 38,000 tons. The total length of the rotating part is 221.3 meters, which is the largest unbalanced rotating cable-stayed bridge of high speed railway in China in terms of tonnage.

How does such a huge object with such a tonnage complete a “gorgeous transformation”? This can’t be done without a high-performance fluoropolymer: teflon sliders. How can a small Teflon slide make a 10,000-ton bridge turn freely?

The basic principle of the rotating body is to set the ball hinge sliding layer between the upper and lower structure of the rotating body which is resistant to high pressure and has a small coefficient of friction. The ball hinge is composed of upper ball hinge, modified teflon slider and lower ball hinge, with the upper and lower ball hinges located in the upper and lower turntable.

In simple terms, the principle is similar to that of a stone grinding disc, where the base does not move and the upper part rotates around the grinding center. So the friction force between the ball hinges needs to be overcome during the traction rotation. How to reduce the frictional resistance is the key technical problem in the construction of the rotating body.

PTFE slider plays such a vital role due to its excellent self-lubrication, lowest dynamic and static friction coefficient, and wear and pressure resistance. After completing the installation of PTFE slider, the upper and lower ball hinges and the central shaft are coated with teflon powder grease lubrication medium, which can minimize the friction. In addition, the rotating shaft has PTFE tube, which can reduce the friction generated in the process of turning the body. Such a small PTFE slider should have such amazing energy!

Features of PTFE

● High temperature resistance

Its working temperature can reach up to 250 ℃.

● Low temperature resistance

It has good mechanical toughness at low temperature; even if the temperature drops to -196 ℃, it can keep 5% elongation.

● Corrosion resistance

It’s inert to most chemicals and solvents, and can resist strong acids and alkalis, water and various organic solvents.

● Good weather resistance

It has the best aging life among plastics.

● High lubrication

PTFE has the lowest coefficient of friction among solid materials.

● Non-adhesive

It has the lowest surface tension among solid materials, and does not adhere to any substance.

Applications of the king of plastics

PTFE can be made into sheets, tubes, rods, films, fibers and coatings according to product classification, and is widely used in various fields such as chemical, petroleum, textile, electrical and electronic, medical, mechanical and aerospace.

● Medical

PTFE is water resistant, physiologically inert, and non-adhesive, so it is used in many tissue repair materials and artificial organ materials, such as artificial blood vessels, and heart repair membranes, etc. PTFE can be sterilized using any method, and will not degrade when heated under high pressure or treated with various disinfectants. Therefore, it is widely used in medical devices such as sutures, sterile pads, and injection needles.

● Electronic and electrical

PTFE has excellent dielectric properties and extremely high thermal stability, and is an irreplaceable electrical insulation material, playing an important role in the field of electrical and electronic insulation. For example, PTFE glass lacquer cloth is used to produce high temperature and high frequency insulation materials, which can be used in satellite communications and computers; PTFE film is used to make capacitors as an insulation layer, padding and cables between instruments; PTFE thin-walled tubes of different calibers can be used for lead wire sleeves, heat shrinkage tubes and spiral tubes, and insulated lead pipes for generators, etc.

In the field of 5G communications, PTFE is also widely used in base station filters, high-frequency high-speed PCB/FPC, 5G chip process and high-frequency connectors and cables. Currently, the 5G filters used by major communication equipment vendors are still made of metal cavity filters, which use many PTFE components for support and insulation.

● Mechanical

For any kind of machine and equipment, lubrication should be conducted for mutual sliding surface during the operation to reduce the friction factor, reduce the wear and heat of the parts, ensure the normal operation capacity, accuracy and power consumption of machine and equipment. PTFE’s low coefficient of friction and self-lubricating properties allow it to be used in the manufacture of bearings, piston rings, machine tool guides and sealing materials, but it is usually used in precision instruments or acid and alkali resistant environments because it’s expensive.

● Textile

Expanded PTFE (e-PTFE) film is laminated with common fabrics to make waterproof and moisture permeable laminated fabrics. Its excellent characteristics of high strength, low shrinkage, non-stick and anti-UV aging enable e-PTFE fiber to become the fabric of choice for outdoor sports clothing. In addition, it is often made into firefighting suits, astronaut suits, medical protective suits, military combat suits, sleeping bags and lightweight tents.

● Automotive & transport

In the automotive oil seal material, it can isolate the parts that need lubrication in the transmission parts from the outgoing parts to prevent the leakage of lubricating oil. PTFE breathable film is used in automotive lights to balance the pressure inside and outside the lights and prevent the pollution brought by water, dust, and automotive fluids, etc.

● Chemical

PTFE, by virtue of its corrosion resistance, is used as an anti-corrosion material to make various anti-corrosion parts, such as pipes, valves, pumps and pipe fittings. For chemical equipment, it can make lining and coating for reactors, distillation towers and anti-corrosion equipment.

Find the best PTFE manufacturer

To make the most use of PTFE products, you’d better choose the best PTFE manufacturer and SuKo, a China well-known PTFE tube manufacturer, is you best choice. Expert in PTFE/UHMWPE extrusion and products in various types and models, Suko stays forefront of the Tetrafluorohydrazine industry with technology innovation,profession and intelligence both domestically and abroad.

Basics Of Multi-lumen Medical Tubing

Multi-lumen tubing extrusion technology

The breakthrough in multi lumen medical tubing extrusion technology has promoted the application of medical tubes to a new level.

In the medical device industry, the minimally invasive surgery rends to require smaller and more innovative medical devices. Devices that act on blood vessels or other tissues require medical tubes with higher precision, tighter tolerances and additional functions. As the tubes are designed more complex, the extrusion technologies to produce them become more complicated. There is no doubt that the multi-lumen tubing extrusion technology is at the forefront of extrusion technology.

Multi-lumen extrusion or co-extrusion can be defined as the simultaneous extrusion of multiple layers of materials to produce multi-lumen medical tubes. Multi-lumen technology is primarily used to improve functionality: combining weldable materials with materials that have certain other performance characteristics, such as lubricity. These structures can also improve performance and potentially reduce overall assembly and material costs, making medical devices more cost-effective for customers; other features may include the addition of active material layers, such as hydrophilic, bioabsorbable or drug-eluting layers. The technologies and materials available to produce multilayer products for medical devices have greatly improved and offer designers a wide range of options for optimized size, material and function.

The functions of medical PTFE multi-lumen tubing in medical devices include: creating tubing surfaces with different characteristics for external and internal surfaces; combining materials with different characteristics to create unique tubing characteristics; enabling active materials to be optimally located; locating bondable materials internally or externally for self-assembly and easy assembly of complex medical devices.

The processing of multi-lumen tubes requires technicians to piece together a wide variety of extruders and downstream equipment. With this poor approach, it is likely that the various extruders will all be in the same plane, resulting in longer flow paths, increased extrusion pressure and increased material processing time. Under such processing method, the required tube layer ratios do not match the optimum output of the extruder, which can result in too high or low screw speeds, and further produce tubes with poor mechanical properties.

Modern multi-lumen tubing extrusion processing equipment is more likely to be a fully integrated production line with a single operator interface that monitors, controls and records the entire extrusion system in real time. Extruders for each polymer layer are selected to provide the desired range of output speeds that do not compromise the mechanical properties of the material. They are positioned to minimize material residence time, and typically one or more extruders can be mounted vertically or at a 45° angle. Typically, one or more extruders in a multi-lumen system will be micro-extruders with a minimum output of 50 grams per hour, allowing an individual layer to be just a few microns thick. Manufacturers of these micro-extruders use innovative extruder designs to ensure that standard plastic pellets travel well through the feed section of the extruder without loss of stability.

Customer expectations are driving the massive use of such statistical process control system and increasing product requirements from regulatory agencies. However, accurate in-line measurement of thin wall medical tubing remains a considerable challenge for medical device manufacturers.

There are still quite a few thermoplastic materials that can be used to design multi-lumen tubes. The most commonly used materials are those traditionally used to make medical tubing, such as polyamide (PA), thermoplastic elastomer (TPE), polyurethane (PU), polyvinyl chloride (PVC), and polyolefin (PE). These materials can be customized to include drug-eluting components, radioactive materials, fillers, and/or colors. However, the designer must consider the processing temperature, flow characteristics and melt viscosity of the material.

Multi-lumen tubing extrusion technology is particularly suitable for extruding novel or active expensive materials that have specific functions because it allows for proper design of the placement of these materials on the medical tubing. A common example is: placing drug-eluting materials on the outer layer of the tubing or placing highly lubricated materials on the inner layer of the tubing. Furthermore, multi lumen medical tubing has cost advantages because thin layers can be placed in the most effective locations.

Applications of multi-lumen tubing in medical industry

Percutaneous replacement of a diseased heart valve is an emerging therapy that offers an alternative to traditional surgical approaches for high-risk patients. In this minimally invasive procedure, a guide wire is passed through the femoral entry site and guided into the heart chambers. A guide sheath is inserted over the guide wire, and the valve delivery system is introduced. The medical tubing required to deliver the valve to the site is a highly specialized component. The distal end must be easily manipulated so that it can be guided directly into the cardiac chamber. The proximal end needs to be more rigid, must have excellent kink resistance, and the inner diameter needs to be lubricated for smooth and unobstructed delivery of replaced valves. Another key requirement is that the wall should be as thin as possible to maximize the delivery path diameter of the replaced valve without the tube losing any of its function.

Designers faced many challenges in designing this particular component. PTFE lubricated liners usually meet the industry standard for delivery systems, but cannot be used due to the possible effects of gamma radiation during sterilization. To ensure that the medical tubing does not kink or deform as it is guided through the anatomy to the heart, a braided layer must be incorporated into the component.

The final design is a five-layer assembly consisting of an ultra-thin-walled multi lumen medical tubing, a braided layer of stainless steel and polyether block amide sheaths of various hardnesses, adding overall proximal to distal flexibility to the outer layer of the assembly.

Conclusion

The innovative use of multi-lumen tubing in medical design has revolutionized the way we solve a large number of medical problems. In the future, as extrusion tools and machine design techniques become more advanced, coupled with improvements in process control and measurement systems, SuKo, one of China top 10 medical tubing companies expect to achieve greater precision with smaller, thinner and more versatile multi-lumen tubes. Over time, multi-lumen extrusion production lines will become more specialized and other extrusion technologies are incorporated such as multi-lumen extrusion, tapered extrusion, and intermittent/interrupted extrusion.

Wednesday, August 17, 2022

Polyteflon Resin Poly Tetra Fluoro Ethylene PTFE Teflon Virgin Molding Powder

Tuesday, August 16, 2022

PTFE Products - Stainless steel braided Teflon liner Tube pipe - The production process

Monday, August 15, 2022

PTFE Products - PTFE Teflon Film by SuKo

Thursday, August 11, 2022

CNC Rotary Cutting Skiving Machine for UHMWPE PTFE Teflon Film

Wednesday, August 10, 2022

PTFE Products - Teflon Super Huge Large Size Tube Rod Plate Pipe

Wednesday, August 3, 2022

PTFE Products - PTFE Teflon Tube Pipe by SuKo

How do medical multi-lumen tubing help the fight against Covid-19

Amid the Covid-19 virus outbreak, medical PTFE multi-lumen tubing is playing an important part in helping fight the global pandemic. In this article, SuKo will explain what medical tubes are, how they’re used and why they’re helping in the fight against Covid-19.

What are medical tubes?

Medical tubes are used as part of equipment to deliver fluids to and from the body, and can also be used for catheters and respiratory equipment. Some medical tubing should be custom produced with different chambers or cores for delivering medication to the body. Medical tubing has become an essential component in the fight against Covid-19 considering the increased number of ICU patients and the increasing demands for ventilators and other respiratory equipment.

What plastic is used for a medical tube?

PTFE is one of the most commonly selected plastics for medical tubing, because it’s adaptable and can be sterilized. Other types of plastic used in medical grade tubing include more flexible materials such as PVC, TPU, TPE, and TPV, etc.

Sterilization and antibacterial properties of medical tubes

Although single-use plastic is frowned upon in everyday life, it can help prevent the spread of viruses and diseases in the medical profession, which is because it’s more hygienic to dispose of items used to treat those with highly contagious viruses rather than to re-use products.

According to medical tubing companies, medical grade plastics should be able to withstand high temperatures and corrosion for optimum cleaning in places where medical equipment is safe to be sterilized and cleaned. Some medical grade plastics can be fitted with anti-bacterial protection to help prevent the spread of contagious illnesses in hospitals and healthcare environments.

How are medical multi-lumen tubes helping the fight against Covid-19?

Medical multi-lumen tubes, key component of medical devices and respiratory equipment including ventilators which aid breathing, have been used in healthcare for many years to enhance patient care and are critical to patient care in intensive care units. As you know, one of the known symptoms of Covid-19 is shortness of breath, which results from the fact that the virus attacks the lungs and pneumonia and respiratory complications will also occur to people with severe symptoms. Therefore, thin wall medical tubing is helping keep patients affected by the disease alive.

Find out more about medical tubing here . If you have an urgent enquiry about medical grade tubing you can contact our team on info@sukoptfe.com.

Tuesday, July 26, 2022

PTFE Teflon High Temperature Adhesive Tape - PTFE Products by SuKo

Sunday, July 24, 2022

Thursday, July 21, 2022

Wednesday, July 20, 2022

PTFE Product - PTFE Corrugated Pipe - Teflon Retractable Tube

Tuesday, July 12, 2022

Friday, July 8, 2022

Top 4 Ways to Prevent The Aging of PTFE Tubes

Nowadays, many products stand out in the development of technologies and industry, and best PTFE tube is one of these products that play an important role in various fields. But have you ever noticed the aging of PTFE tubes? The performance of PTFE tubes will also be reduced after aging. So a series of measures should be taken to prevent the aging at the later stage of the production of PTFE tubes. The aging of PTFE tubes is natural and cannot be prevented, but the only thing you can do is to slow the aging speed of PTFE tubes. To help slow down the aging rate of PTFE tubes, you should strengthen maintenance in using PTFE tubes and take a series of measures to prevent this situation. Here Suko offers you the major four methods to slow down the aging speed of your PTFE tube.

1. When choosing the sizing material of PTFE tubes, you should use sulfur curing system whenever possible. Due to the heat resistance of its vulcanized rubber, it can be modified by reducing or avoiding the use of elemental sulfur, which can minimize or remove polysulfide crosslinks and produce mainly monosulfide or disulfide crosslinks, thus slowing down the aging of teflon tubes.

2. To ensure that the material achieves the desired heat resistance, the use of peroxide is required. In this case, peroxide vulcanization produces carbon with better thermal stability and carbon cross-linking bonds. PTFE tube manufacturer also notes that you should pay special attention to other additives in the use of peroxides. For example, the choice of antioxidants needs to be more stringent, as many of them interfere with the vulcanization of peroxides. Therefore, you can also use paraffin oil, an effective additive that will not interfere with peroxide vulcanization.

3. In addition, in order to prevent the partitioning of the peroxide cation and avoid too low vulcanization of the high-pressure hose (indicated by lower hardness, lower modulus and higher compression and long-term deformation), you should use peroxide to reduce the amount of acidic filler. If possible, the addition of alkaline compounds (e.g. zinc oxide or magnesium oxide) usually improves the cross-linking efficiency of the peroxide.

4. When producing best ptfe tubes, some additives can be added, such as antioxidants, and alkaline compounds, etc., so as to improve the cross-linking efficiency of peroxides and delay the aging of teflon tubes.

Tuesday, July 5, 2022

Expanded PTFE VS. PTFE: What’s The Difference?

You must know PTFE, the father of fluoroplastics. But what is expanded PTFE ? Also known as ePTFE, expanded PTFE is the microporous version of PTFE. ePTFE enjoys similar properties to PTFE. This article will describe the differences between them and their respective applications.

PTFE: the father of fluoroplastics

What is PTFE?

As a polymer compound made of tetrafluoroethylene by polymerization, PTFE has excellent chemical stability and corrosion resistance, and has become one of the materials with best corrosion resistance. PTFE can resist almost all the chemicals, except molten alkali metal, chlorine trifluoride, chlorine pentafluoride and liquid chlorine, so it has been widely used in various occasions to resist acid and organic solvent. PTFE itself is not toxic to people.

Unique properties of PTFE

PTFE is the most unusual fluoropolymer and exhibits the best performance in terms of temperature, chemical resistance and non-stick properties.

● Cost-effective;

● Continuous working at temperature of +260°C;

● Low friction surface;

● Very high electrical resistance.

Applications of PTFE

● According to PTFE manufacturers, PTFE has the following major applications.

● Endure even the harshest of environments and is suitable for use in numerous applications.

● Ideal for use in the food and drink production, including cooking equipment, conveyor belt rollers, non-stick surface covers, and temperature sensor casing.

● Particularly useful for the production of internal and external life-saving equipment.

● Perfect for electrical insulation and protection of electronic components.

● Make different products in the chemical industry, such as gaskets, vessel linings and chemical tanks.

Expanded PTFE: the microporous fluoropolymer

What is expanded PTFE?

Expanded PTFE (ePTFE) is a new type medical polymer material, which is made of polytetrafluoroethylene resin by stretching and other special processing methods. The white, elastic and flexible expanded PTFE has a mesh structure formed through microfiber connection, and these microfibers form countless pores, so that the expanded PTFE can be arbitrarily bent. Its good blood compatibility and biological aging resistance allow it to be used in the manufacture of artificial blood vessels, heart patches and other medical products and become the most ideal biological tissue substitute. With good biocompatibility and unique microporous structure, ePTFE is non-toxic, non-cancerous, and non-allergenic, and will produce no other side effects. Human tissue cells and blood vessels can grow into its micro-pores and then form tissue connections as autologous tissue.

Unique properties of expanded PTFE

Expanded PTFE shares similar properties to PTFE. The material is completely non-toxic and hygienic, and also offers working temperatures up to 260°C. In addition, ePTFE enjoys the following properties.

● Chemically resistant with high linear strength;

● Chemically inert;

● Watertight at low pressure;

● Low dielectric constant;

● Excellent radial expansion and UV resistance.

Applications of ePTFE

1. Medical implants

Purely inert ePTFE can be used in a variety of rehabilitation solutions, including artificial blood vessels and patches for soft tissue regeneration and surgical sutures for vascular, cardiac, general and orthopedic surgery, thereby benefiting both physicians and patients. The ePTFE medical products are able to work in harmony with the body’s own tissues and restore their normal function.

2. Fluorofiber

Expanded PTFE fibers have high strength, low shrinkage, abrasion resistance, and extreme UV resistance, thus ensuring good stability and integrity in extreme environments. This kind of fiber is very versatile and can be woven, spun, braided or sewn into a variety of fabrics, including compression packaging, sewing thread, construction fabrics and dental floss.

3. Gaskets and sealant

ePTFE has excellent chemical and abrasion resistance and extreme resistance to high and low temperatures, making it highly suitable for transporting and sealing of industrial fluids. Gaskets and sealing products from Suko, including flat, thin strip and field-formed sealants, are available for flanges of any size or specification.

Thursday, June 30, 2022

Ball press molding machine for ptfe teflon plastic polymer ball by SuKo

Tuesday, June 28, 2022

Best cutting solution for sealing PTFE gaskets

PTFE gaskets, also known as Teflon gaskets, are widely used as sealing and filling materials in petroleum, chemical, pharmaceutical, electric power, steel and other industries for their excellent material properties. And the great empowering values created by Teflon gaskets should not be underestimated. Today, let’s talk about knowledge about PTFE gaskets and PTFE gasket molding equipment.

Teflon gasket is a polymer compound made of tetrafluoroethylene by polymerization, which has excellent chemical stability, corrosion resistance, sealing, non-toxicity, high lubrication, non-adhesion, electrical insulation, age resistance, and many other excellent characteristics. Therefore, it has been widely used in various applications.

As one of the best corrosion resistant materials, PTFE gasket has solved many problems in the areas of chemical, petroleum and pharmaceutical. Meanwhile, it has a variety of applications as a sealing material. How to better cut and process PTFE to solve the problems of complicated punching operations, serious material wastes, low utilization rate and secondary grinding processing has become the key focus of many gasket manufacturers.

With the market becoming intelligent and mechanized, manual operation has been gradually replaced by machines, and laser machine, an insulation cutting machine, is not suitable for the cutting of all the materials, which will easily produce odor or material damage, thus reducing sales volume.

Highly efficient and accurate PTFE gasket automatic press molding machines are designed to improve production efficiency and product quality, and promote the green and sustainable development of the production chain. This kind of machine can meet customers’ needs and guarantee product quality in a more efficient and precise manner in the era of intelligent automation.

Established in 2006, Suko has over 13 years of manufacturing experience in PTFE/UHMWPE extrusion machinery and equipment for special applications in the field of plastics processing, and stays forefront of the Tetrafluorohydrazine industry with technology innovation, profession and intelligence both domestically and abroad.

|

Monday, June 20, 2022

Understanding The Benefits Of PTFE Tubing

PTFE tubing is an example and brings great benefits to your life. Continuous development of the society creates a large number of excellent products in your life to meet your various needs. This extremely versatile product provides for an extensive list of applications in many different industries. Check out this post to learn about benefits of PTFE tubing!

|

|

| SuKo PTFE Medical multi-lumen tubing | SuKo PTFE Teflon Brake Hose |

1. Outstanding corrosion resistance. Various polymers will break down if they make contact with the wrong type of chemical. Teflon tubing can withstand highly corrosive environments such as acid and alkali, making it ideal for a number of different chemical and hazardous environment applications.

2. Smooth and flat inner surface. This kind of surface can increase the speed of pipe circulation and reduce the resistance of conveying, so that you can increase the speed and improve the efficiency when conveying objects.

3. tubing made in PTFE are made to be highly resistant to heat and high temperatures. This sort of benefit makes it perfect for use in machines and automobiles where it may be subjected to high amount of heat and temperatures. When the temperature rises, some polymers will not last and will melt or warp and make messes for maintenance and operating crews. If you expect the heat inside or outside the tubing to rise, choose PTFE for its ability to withstand extreme heat and cold.

Besides these three benefits above, PTFE tubing also has other advantages. Its various features and benefits determine its wide application fields. PTFE tubing manufacturers conclude that PTFE tubing are mainly used in the applications such as household appliances, medical applications, automobile industry, food industry, plastics and rubber industry, and paper making and fiber industry.

SuKo provides PTFE tubing in a range of sizes, thicknesses, and lengths for every application. Let us know what you expect from your tubing solution, and special specifications can be customized. If you have any interest, please contact us. We will response to you as soon as possible.

Thursday, June 9, 2022

SPECIAL APPLICATIONS OF PTFE TUBING

PTFE Teflon tubing has remarkable non-adhesive property, and colloid and chemicals will not be adhered to the inner wall of Teflon tubing, so no dirt layer will be formed inside the pipe. Teflon is a highly non-polar material with electrical insulation properties and great resistance. Its dielectric constant is about 2.0, smaller than all the other electrical insulation materials, and changes in temperature and frequency have basically no effect on Teflon tubing.

Excellent aging resistance, radiation resistance and thermal stability allow PTFE tubing to be used in outdoor for a long time. Teflon has perfect non-inflammability and a limiting oxygen index of over 95, so it can only melt on the flame, but generate no molten droplets, and it has to be carbonized finally. It has high flexibility and good resistance to bending. Moreover, it has great resistance to moisture, so Teflon surface coating is not stained with water and oil, and solution is hard to be stained during production operation. A small amount of dirt can be removed by simple wiping. PTFE tubing has short downtime, thus saving working hours and improving efficiency. Next SuKo explains three special applications of PTFE tubing to help you make better use of Teflon tubes.

1. Resistance to high temperature, corrosion and high pressure

A Teflon Steel Braided Hose is made of special high-grade PTFE hose, high temperature resistant braided mesh and advanced stainless steel double-buckle spiral hose, so it is suitable for special environment of high temperature, corrosion and high pressure.

The hose can withstand 250°C high temperature steam inside under 3kg/cm2 air pressure, while the skin temperature does not exceed 60°C to ensure operational safety. It can be used normally under 10kg/cm2 steam pressure.

2. Light weight and strong softness

The specially assembled hose with a total length of 2m (including both ends of the joint) weighs only 500g, and can greatly reduce the workload of the operator. Its high softness and flexible bending will not obstruct the ventilation.

3. High resistance to vandalism

Advanced technologies are adopted in stainless steel double buckle self-locking spiral hose protection, so PTFE Teflon tubing can withstand 180kg of tension and will not be damaged during normal use.

Tuesday, May 24, 2022

Monday, May 23, 2022

EVERYTHING YOU NEED TO KNOW ABOUT PTFE RODS

What is a PTFE rod?

PTFE rods, also known as Teflon rods, are unfilled PTFE resin (can contain recycled PTFE resin) molded, paste extruded or plunger extruded for processing various gaskets, seals and lubricating materials that work in corrosive media and electrical insulation parts used at various frequencies. Plunger extrusion process to form the rod.

|

|

Main properties of PTFE rod

Operating temperature: from -200℃ to 260℃; easy processability; aging resistance: it can be exposed to ozone and sunlight for a long time without aging; corrosion resistance: it can withstand strong acids, strong oxidizing agents, strong reducing agents and various organic solvents except molten alkali metals and fluorinated media; outstanding electrical insulation properties.

Other characteristics

Density: 2.16-2.20g/cm3; volume resistance>1×1018; surface resistance>2×1013; arc resistance>165s; water absorption<0.1%; low friction coefficient; non-adhesive surface: solid materials cannot adhere to its surface; non-combustibility: it will not burn in the air; non-toxic: it’s non-toxic, odorless and physiologically inert, and causes no harm to people and the environment.

Applications of PTFE rod

There are two kinds of PTFE rods: pressed rods and molded rods. Due to excellent chemical resistance and dielectric properties, and minimized friction coefficient, PTFE rods are mainly applied to long products and mechanical parts with non-standard specifications such as seals/gaskets, rings, wear-resistant plates/seat electricity, insulating parts, mechanical parts, and linings in the fields of oil and gas, petrochemical, chemical, instrument and equipment.

Chemical industry: It can be used as anti-corrosion material, produce various anti-corrosion parts, such as pipes, valves, pumps and pipe fittings, and act as the linings and coatings of reactors, distillation towers and anti-corrosion equipment.

Mechanical industry: It can be used as self-lubricating bearings, piston rings, oil seals and sealing rings, etc. Its self-lubrication can reduce wear and heat generation of machine parts and reduce power consumption.

Electronic appliances: It is mainly used in the manufacture of various wires and cables, battery electrodes, battery separators, and printed circuit boards, etc.

Medical materials: Its heat-resistant, water-resistant and non-toxic properties enables itself to be used as sealing and filling materials for medical devices (sterilization filters, beakers, artificial heart and lung devices) and artificial organs (artificial blood vessels, heart and esophagus).

SuKo PTFE Teflon Rod Extruder

1. Complete set of ptfe equipment manufacturer - Push bar machine line: bar extruder, mold design, heating ring, automatic feeding one-stop service.

2. PLC intelligent control: continuous extrusion, sintering, self-adjusting concentricity, automatic feeding, feeding equipment can be used for 6-8 hours, no manual.

3. Extrusion rod quality: smooth surface, high tensile strength, high density.

4. Professional technical guidance: installation and debugging, operation and operation, process setting, maintenance, after-sales service, raw material channel.

Monday, May 16, 2022

THREE COMMON PROBLEMS WITH PTFE TUBES

PTFE tube or Teflon tube, a semi-transparent, chemically inert and non-toxic material, has been mostly used in applications requiring resistance to high temperatures, including medical and health care, chemical, aviation, national defense, cutting-edge science and technology, and mechanical engineering, etc. One of its unique features is temperature resistance and its working temperature is from -190℃ to +260℃, so it can be used in elevated temperature applications which require high temperatures of over 200℃. PTFE tubes have very good chemical resistance to common solvents, acids, alkali and bases, and excellent dielectric insulation properties.

|

|

Do you meet any problems when using a PTFE tube? Here SuKo Polymer Machine Tech Co., Ltd., a well-known China PTFE tube manufacturer and exporter, explains three typical problems to help you make better use of PTFE tubes.

1. How to connect PTFE tubes?

The continuous advancement of anti-corrosion technologies and innovation of anti-corrosion materials promote PTFE to be an attractive anti-corrosion material due to its excellent chemical stability, and high temperature and chemical corrosion resistance. But PTFE material has high lubricity and non-adhesive property, making it difficult to connect PTFE tubes. To solve this problem, hot air welding method and manual flanging method can be adopted to connect PTFE tubes.

2. Precautions of PTFE tube installation

The lined plastic is soft when drilling, but it is more troublesome to force a rigid drill bit, which will easily destroy the internal steel lined plastic pipe and cause edges to be hard to be flush, so it is recommended to use a cutter to open the hole. Lined plastic residues will fall into the original PTFE tubes during the hole opening process, so you should pay more attention during the operation, otherwise it will lead to blocked end water points. No electric welding tool should be used for punching holes or installing branch pipes, otherwise lined plastic of steel PTFE tubes will be destroyed.

3. How to treat the surface of PTFE tubes?

The surface of a PTFE tube should not come into contact with aggressive materials such as oil, solvents, and corrosive materials, etc. The surface should be cleaned with water and detergent and rinsed well after staining. The use of solvents and corrosive cleaning materials is prohibited.

You may encounter other problems when use a PTFE tube except these three problems, and don’t worry. You can find SuKo and will get necessary guidance and help.

Tuesday, May 10, 2022

Sunday, May 8, 2022

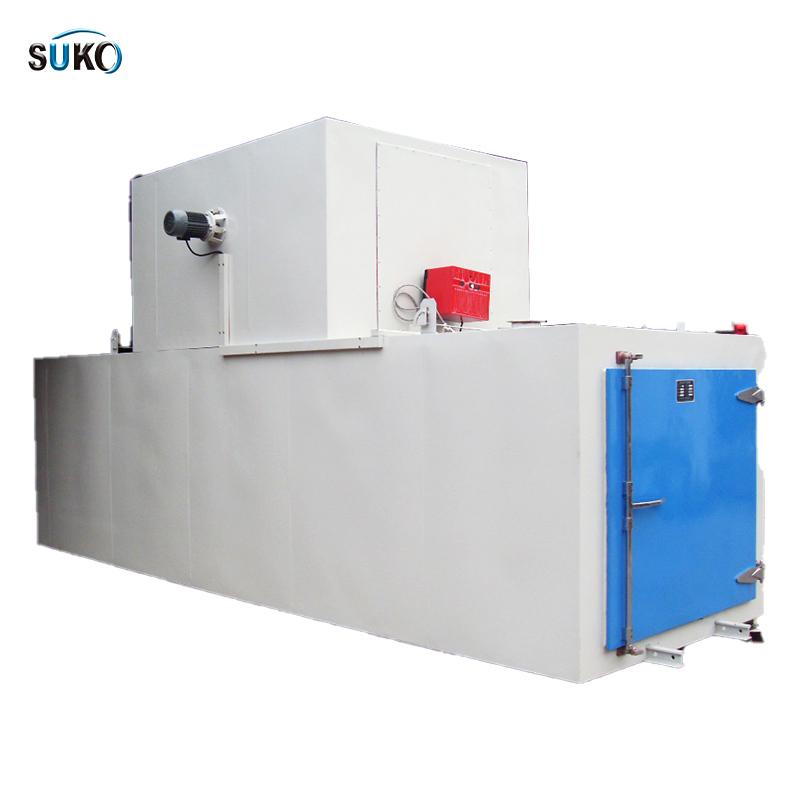

What is PTFE sintering furnace?

PTFE sintering furnace is a special furnace applied to the drying of PTFE in the aviation, automotive, household appliances, scientific research and other fields, to test and determine the parameters and performance of electricians, electronics, products and materials after temperature changes.

Features and advantages

|

|

1. High temperature resistance, and excellent insulation performance.

2. Steam preheating and electric heating compensation are often used, resulting in high thermal efficiency and low operation cost.

3. The internal monitoring temperature is consistent with PTFE temperature, and heating, draining, drying and cooling functions can meet the requirements of PTFE drying process.

4. PTFE sintering furnace runs smoothly with the minimized noise.

5. Easy installation and maintenance, and intelligent human-machine interface operation.

Components

The PTFE sintering furnace is mainly composed of furnace body, hearth, steam heat exchanger, electric heater, support, circulating fan, moisture discharging fan, refractory material and electric heating device, etc.

1. The furnace body has the frame structure, and its full-welding inner cavity, making it easier to clean.

2. Composite insulation minimizes the heat transferred between inner skeleton and outer skeleton. Unexposed insulation materials ensure that the average temperature rise of the outer wall of the furnace body remains within 20 ℃ higher than the ambient temperature, thus effectively preventing heat loss.

3. The hearth is firm and durable, and will not be deformed. Pressure bar locks are used in the hearth and the furnace body. Silicone rubber is used as the sealing material, to ensure that the hearth is sealed tightly.

4. Preheating of steam heater and compensation of electric heater inside the furnace realizes the temperature control accuracy of ±0.5 ℃. Multi-point dual-setting temperature measurement ensures true and reliable monitoring temperature and provides over-temperature alarm function.

5. Axial circulating fan with large air volume and low noise, together with movable perforated plate, ensures uniform temperature in the PTFE sintering furnace and avoids dust flying.

6. The bearing seat of the circulating fan is well sealed and equipped with oil slinger, to prevent lubricants into the furnace.

7. Controlled by frequency conversion, the moisture discharging fan discharges the moisture according to the process requirements.

|

|

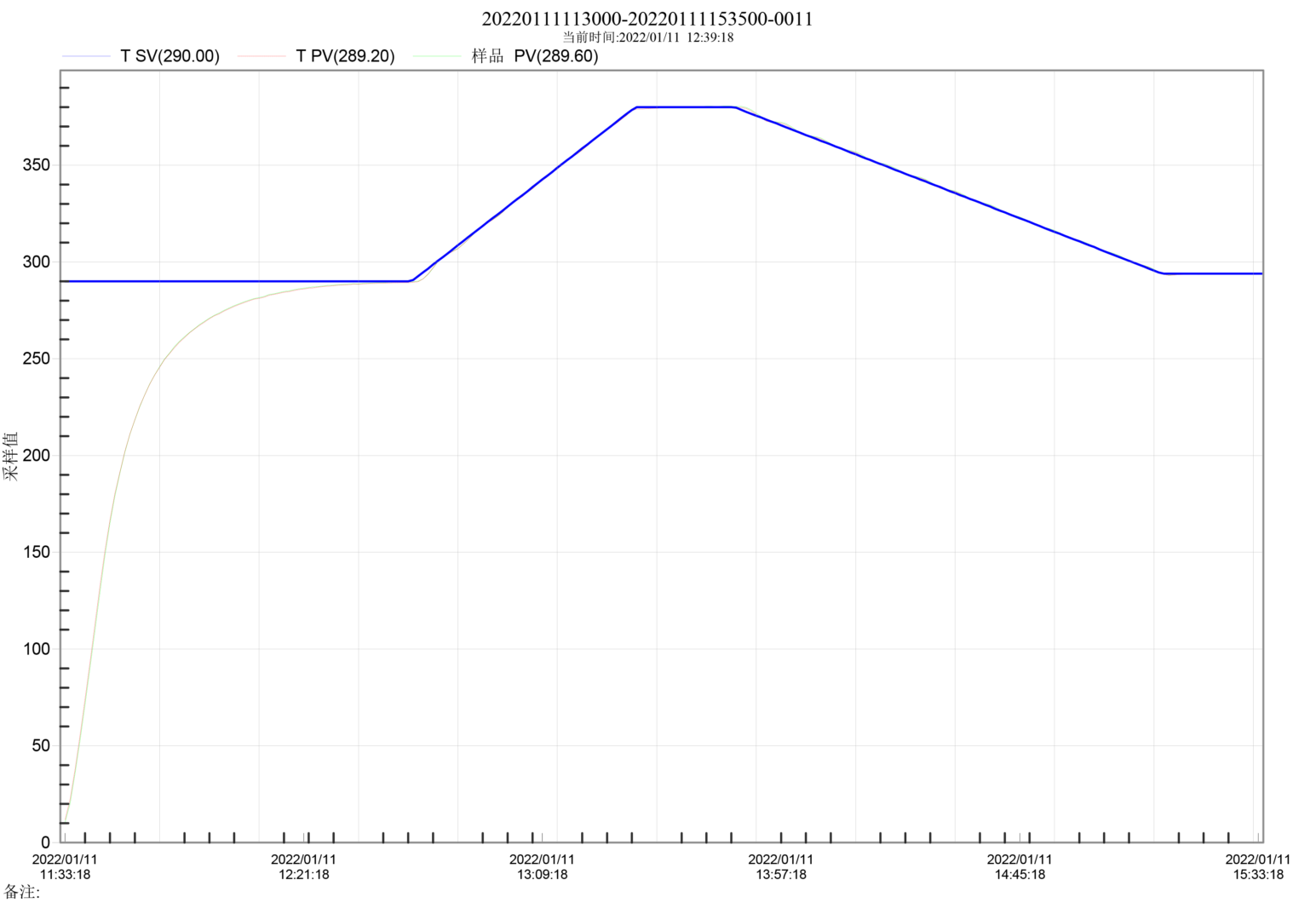

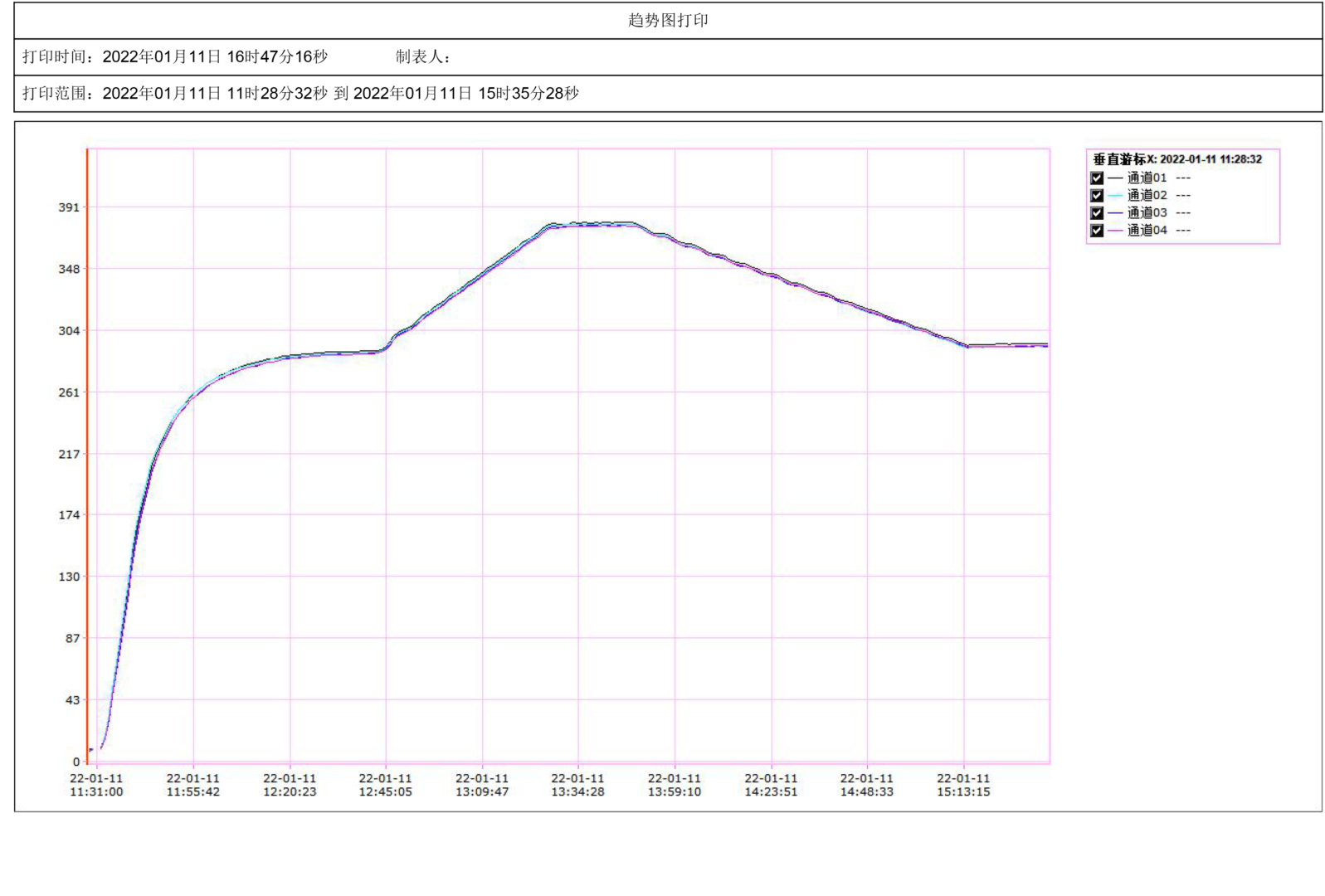

SuKo Polymer Machine Tech Co., Ltd. As an experienced and patented manufacturer, we manufacture PTFE sintering furnaces. It can ensure that the temperature in the corner of the furnace is almost the same as that in the center, and the temperature can be accurately changed according to the setting of the control panel. Temperature sensor tests at the corner and center are shown as follows:

|

|

Corner temperature detector temperaturerecording curve |

Central temperature detector temperaturerecording curve |