Thursday, June 30, 2022

Ball press molding machine for ptfe teflon plastic polymer ball by SuKo

Tuesday, June 28, 2022

Best cutting solution for sealing PTFE gaskets

PTFE gaskets, also known as Teflon gaskets, are widely used as sealing and filling materials in petroleum, chemical, pharmaceutical, electric power, steel and other industries for their excellent material properties. And the great empowering values created by Teflon gaskets should not be underestimated. Today, let’s talk about knowledge about PTFE gaskets and PTFE gasket molding equipment.

Teflon gasket is a polymer compound made of tetrafluoroethylene by polymerization, which has excellent chemical stability, corrosion resistance, sealing, non-toxicity, high lubrication, non-adhesion, electrical insulation, age resistance, and many other excellent characteristics. Therefore, it has been widely used in various applications.

As one of the best corrosion resistant materials, PTFE gasket has solved many problems in the areas of chemical, petroleum and pharmaceutical. Meanwhile, it has a variety of applications as a sealing material. How to better cut and process PTFE to solve the problems of complicated punching operations, serious material wastes, low utilization rate and secondary grinding processing has become the key focus of many gasket manufacturers.

With the market becoming intelligent and mechanized, manual operation has been gradually replaced by machines, and laser machine, an insulation cutting machine, is not suitable for the cutting of all the materials, which will easily produce odor or material damage, thus reducing sales volume.

Highly efficient and accurate PTFE gasket automatic press molding machines are designed to improve production efficiency and product quality, and promote the green and sustainable development of the production chain. This kind of machine can meet customers’ needs and guarantee product quality in a more efficient and precise manner in the era of intelligent automation.

Established in 2006, Suko has over 13 years of manufacturing experience in PTFE/UHMWPE extrusion machinery and equipment for special applications in the field of plastics processing, and stays forefront of the Tetrafluorohydrazine industry with technology innovation, profession and intelligence both domestically and abroad.

|

Monday, June 20, 2022

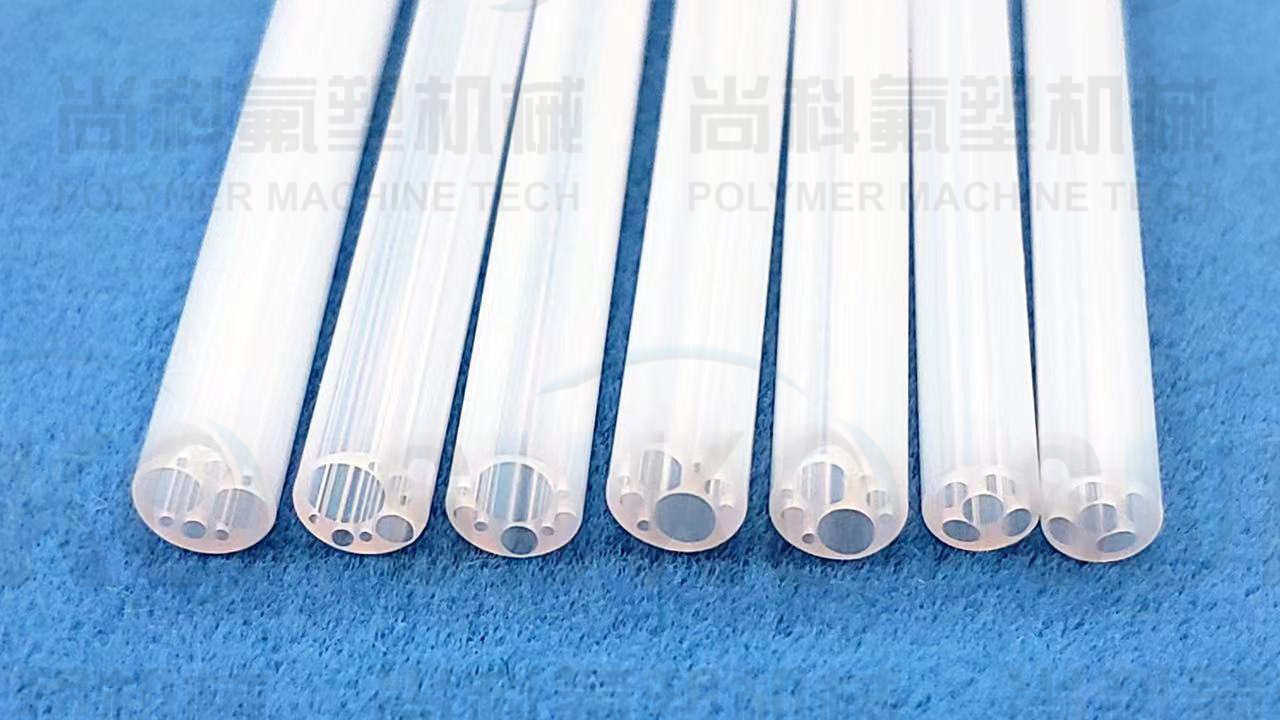

Understanding The Benefits Of PTFE Tubing

PTFE tubing is an example and brings great benefits to your life. Continuous development of the society creates a large number of excellent products in your life to meet your various needs. This extremely versatile product provides for an extensive list of applications in many different industries. Check out this post to learn about benefits of PTFE tubing!

|

|

| SuKo PTFE Medical multi-lumen tubing | SuKo PTFE Teflon Brake Hose |

1. Outstanding corrosion resistance. Various polymers will break down if they make contact with the wrong type of chemical. Teflon tubing can withstand highly corrosive environments such as acid and alkali, making it ideal for a number of different chemical and hazardous environment applications.

2. Smooth and flat inner surface. This kind of surface can increase the speed of pipe circulation and reduce the resistance of conveying, so that you can increase the speed and improve the efficiency when conveying objects.

3. tubing made in PTFE are made to be highly resistant to heat and high temperatures. This sort of benefit makes it perfect for use in machines and automobiles where it may be subjected to high amount of heat and temperatures. When the temperature rises, some polymers will not last and will melt or warp and make messes for maintenance and operating crews. If you expect the heat inside or outside the tubing to rise, choose PTFE for its ability to withstand extreme heat and cold.

Besides these three benefits above, PTFE tubing also has other advantages. Its various features and benefits determine its wide application fields. PTFE tubing manufacturers conclude that PTFE tubing are mainly used in the applications such as household appliances, medical applications, automobile industry, food industry, plastics and rubber industry, and paper making and fiber industry.

SuKo provides PTFE tubing in a range of sizes, thicknesses, and lengths for every application. Let us know what you expect from your tubing solution, and special specifications can be customized. If you have any interest, please contact us. We will response to you as soon as possible.

Thursday, June 9, 2022

SPECIAL APPLICATIONS OF PTFE TUBING

PTFE Teflon tubing has remarkable non-adhesive property, and colloid and chemicals will not be adhered to the inner wall of Teflon tubing, so no dirt layer will be formed inside the pipe. Teflon is a highly non-polar material with electrical insulation properties and great resistance. Its dielectric constant is about 2.0, smaller than all the other electrical insulation materials, and changes in temperature and frequency have basically no effect on Teflon tubing.

Excellent aging resistance, radiation resistance and thermal stability allow PTFE tubing to be used in outdoor for a long time. Teflon has perfect non-inflammability and a limiting oxygen index of over 95, so it can only melt on the flame, but generate no molten droplets, and it has to be carbonized finally. It has high flexibility and good resistance to bending. Moreover, it has great resistance to moisture, so Teflon surface coating is not stained with water and oil, and solution is hard to be stained during production operation. A small amount of dirt can be removed by simple wiping. PTFE tubing has short downtime, thus saving working hours and improving efficiency. Next SuKo explains three special applications of PTFE tubing to help you make better use of Teflon tubes.

1. Resistance to high temperature, corrosion and high pressure

A Teflon Steel Braided Hose is made of special high-grade PTFE hose, high temperature resistant braided mesh and advanced stainless steel double-buckle spiral hose, so it is suitable for special environment of high temperature, corrosion and high pressure.

The hose can withstand 250°C high temperature steam inside under 3kg/cm2 air pressure, while the skin temperature does not exceed 60°C to ensure operational safety. It can be used normally under 10kg/cm2 steam pressure.

2. Light weight and strong softness

The specially assembled hose with a total length of 2m (including both ends of the joint) weighs only 500g, and can greatly reduce the workload of the operator. Its high softness and flexible bending will not obstruct the ventilation.

3. High resistance to vandalism

Advanced technologies are adopted in stainless steel double buckle self-locking spiral hose protection, so PTFE Teflon tubing can withstand 180kg of tension and will not be damaged during normal use.